The Problem with Manual Maintenance Management

If you’ve ever relied on sticky notes, voicemails, or spreadsheets to manage maintenance, you know how quickly things slip through the cracks. Manual processes mean:

- Repairs get delayed because requests aren’t prioritized consistently.

- Teams waste time chasing information or duplicating work.

- Emergencies get lumped in with non-urgent issues, creating inefficiencies.

This approach is reactive and costly. Property managers end up putting out fires instead of focusing on prevention or optimization. Residents wait longer than they should, staff morale dips, and expenses climb.

Manual maintenance management was never built to handle today’s pace and scale of property operations. That’s where automation changes everything.

How Data-Driven Automation Works in Practice

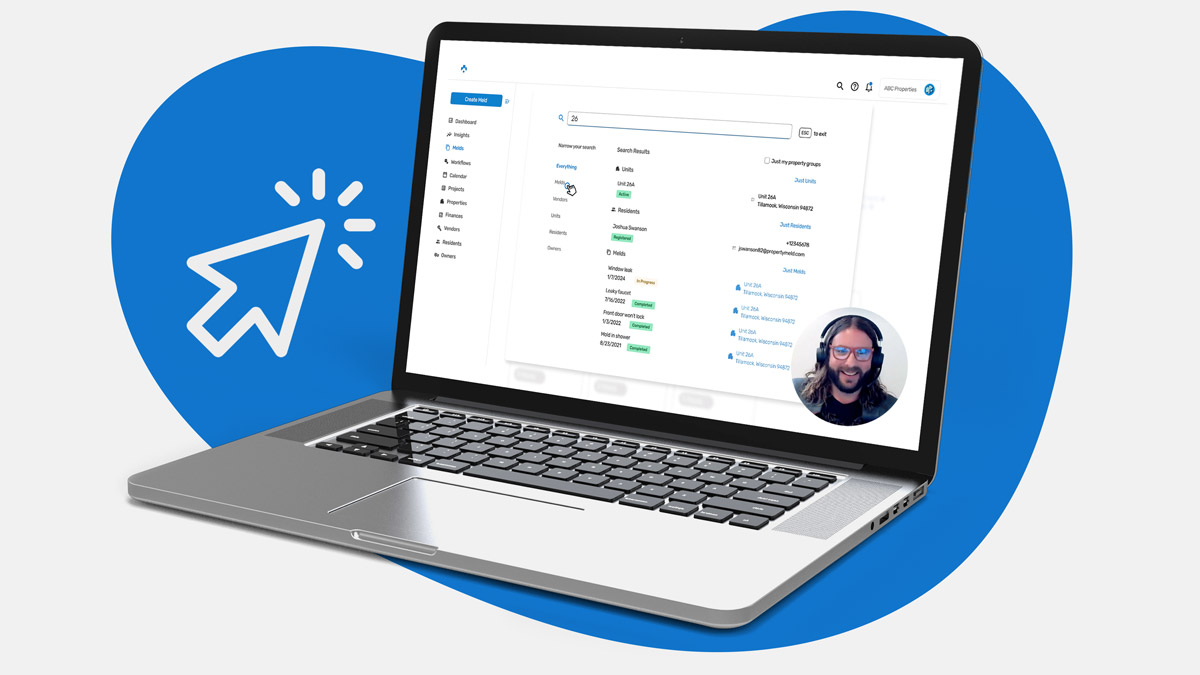

At its core, data-driven automation uses information from every request, repair, and outcome to drive smarter decisions. Instead of a human deciding in the moment what’s urgent or how to route a job, automation handles it based on consistent rules and machine learning.

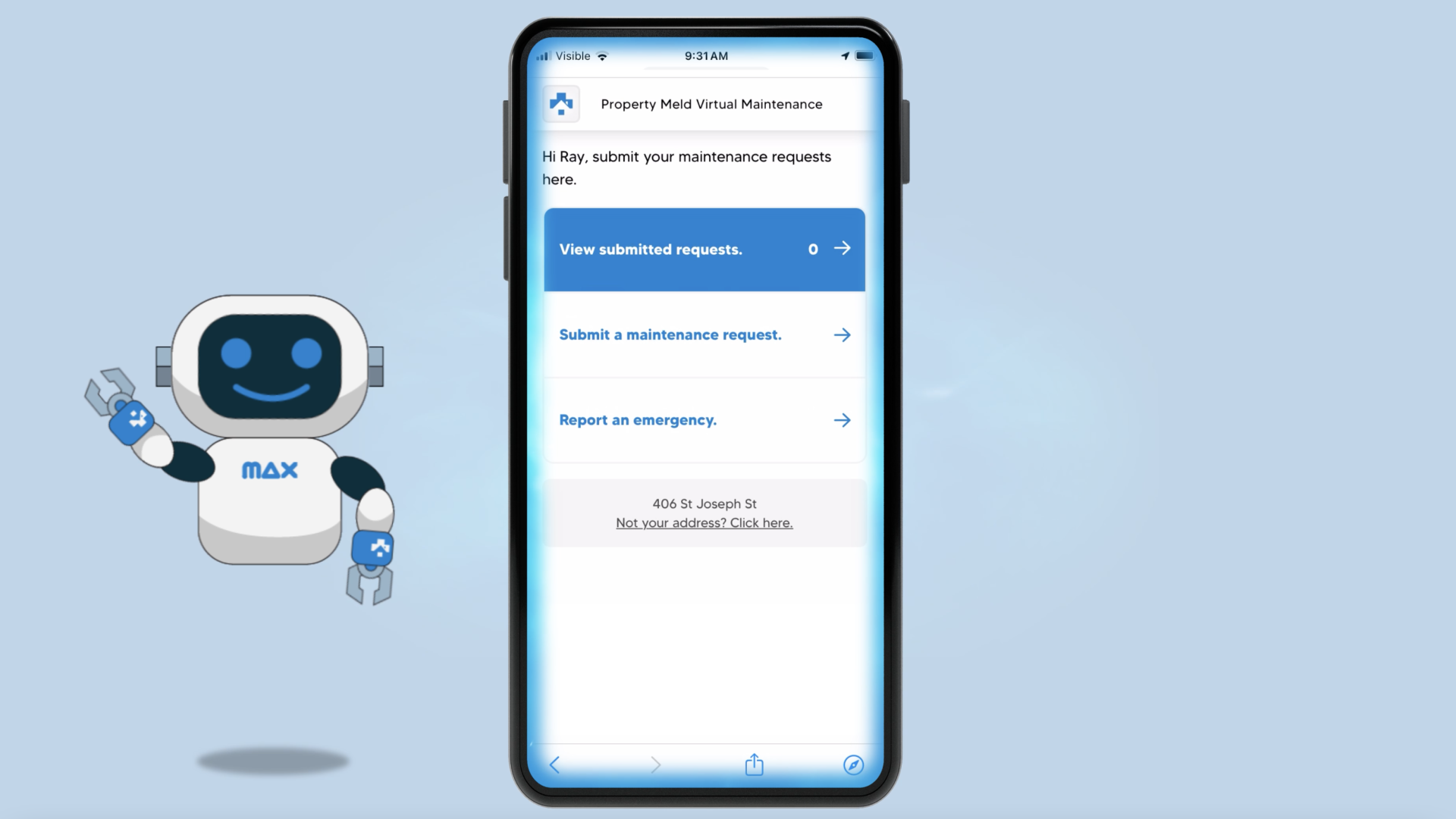

Here’s how it works with MAX™ Intelligence:

- Digital intake: Every request comes in with the right details logged instantly.

- Automated triage: The system prioritizes issues based on urgency and context.

- Smart scheduling: Technicians are matched with the right job at the right time, reducing wasted trips and idle hours.

- Continuous learning: Each request adds to the data pool, making the system smarter and more accurate over time.

The result is a system that doesn’t just react, it learns and improves.

Cost-Saving Benefits of Automation

Data-driven automation is not just about speed. It’s also about protecting the bottom line.

Lower labor costs

By automating triage and scheduling, teams spend less time on administrative work and more time resolving actual maintenance issues.

Fewer unnecessary dispatches

Intelligent automation can distinguish between a true emergency and a routine request, preventing wasted trips after hours or overtime charges.

Optimized resource use

When jobs are prioritized and routed efficiently, technicians complete more repairs in less time, maximizing their productivity.

Long-term savings

Because the system continuously learns, it helps identify recurring issues or inefficiencies, allowing property managers to make proactive changes that reduce costs over time.

Examples of Faster Repairs with MAX™ Intelligence

Here’s how MAX™ Intelligence brings these benefits to life:

- Scenario 1: A resident reports no heat in winter. MAX™ flags it as urgent, assigns the right technician, and ensures immediate attention. Downtime is minimized, and residents feel supported.

- Scenario 2: A leaky faucet comes in at midnight. MAX™ identifies it as non-urgent, schedules it for the next day, and saves the team from an unnecessary after-hours call.

Each example shows how automation speeds up response times while preventing wasted resources.

Data-driven automation is no longer a “nice to have” in property maintenance, it’s the future. By leveraging intelligent automation and machine learning, property managers can cut costs, reduce stress on their teams, and keep residents happier with faster, smarter repairs.

With MAX™ Intelligence, you’re not just fixing problems. You’re transforming maintenance into a proactive, cost-efficient operation.

Ready to see how MAX™ speeds up repairs while lowering costs?